TANIQ’s Hybrid Robotic Filament Winding & AFP System: The Next Evolution in Composites

In today’s rapidly advancing composites industry, Filament Winding (FW) and Automated Fiber Placement (AFP) have emerged as two key processes for manufacturing high-performance components—from pressure vessels and hydrogen tanks to aerospace structures and more. While each method has its strengths (FW for speed, AFP for precision), blending them under one roof was once considered a complex challenge.

At TANIQ, we’re leading the next wave of innovation by offering a single, integrated robotic system that seamlessly combines the best of FW and AFP. Leveraging towpreg—a pre-impregnated fiber material renowned for its tacky surface—we can alternate between high-speed winding and precision placement on the same machine. And to streamline it all, we developed our proprietary TaniqWind Pro software, delivering a unified environment for design, simulation, and production.

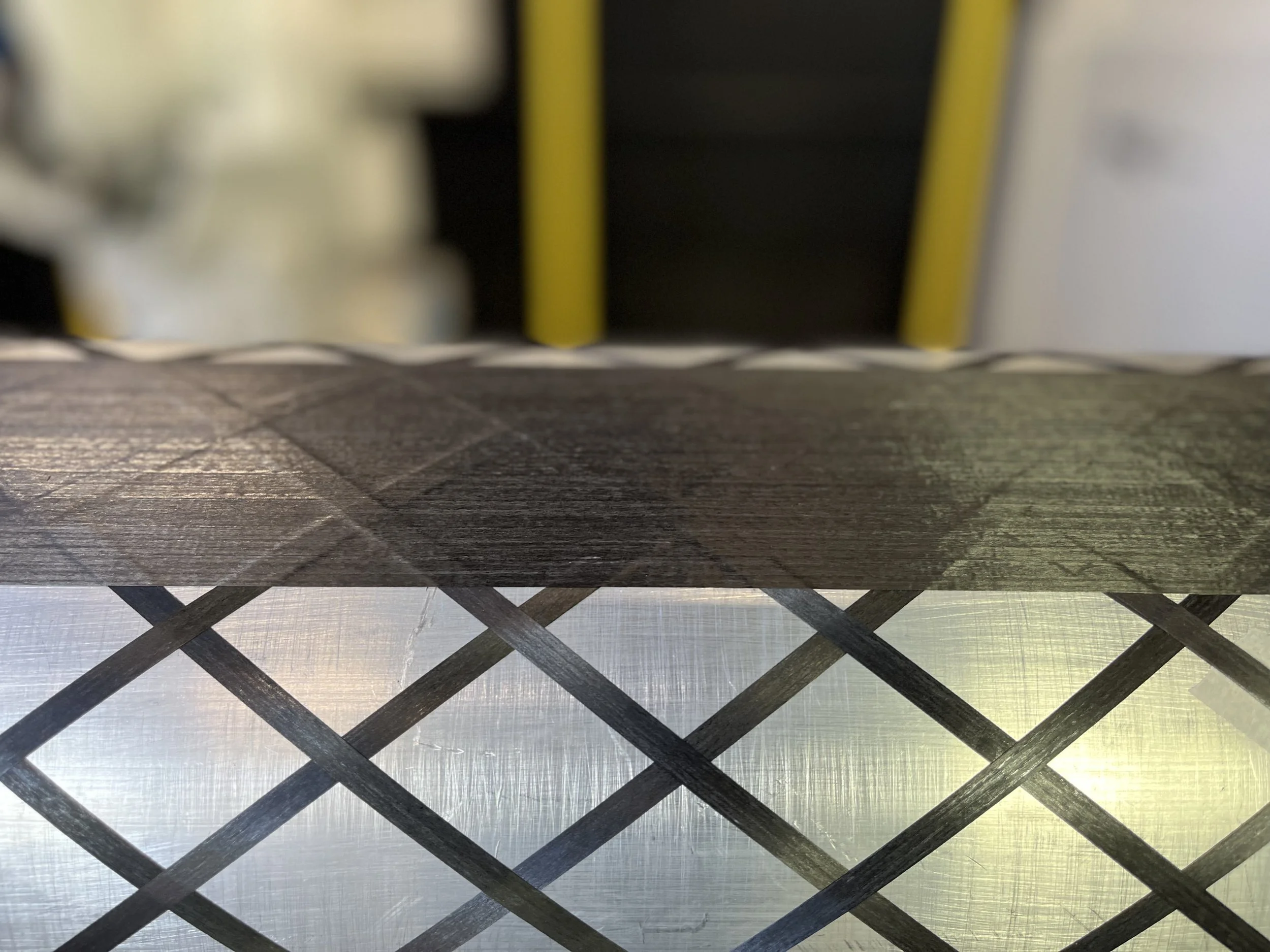

Image at TANIQ’s R&D facility showing an AFP process test on a pressure vessel mandrel demonstrating process accuracy and speed.

1. Robotic Filament Winding (FW) for High-Speed Production

Traditional Filament Winding has long been a go-to method for manufacturing robust cylindrical structures like pipes, pressure vessels, and rocket components. However, robotic FW steps it up a notch:

Maximum freedom of motion: The robotic winding process provides additional degrees of freedom enabling to increase the winding speed on complex-shaped parts.

Cleaner & More Consistent: By using towpreg TANIQ’s system avoids many of the mess and speed limitations of wet winding, and maximizes the fiber volume content in the product.

Continuous Innovation: Far from outdated, FW keeps evolving through new materials, improved resin formulations, and advanced automation—making it more relevant than ever.

2. Automated Fiber Placement (AFP) for Local Reinforcement

While FW excels at winding continuous layers at high speed, AFP shines where nuanced, localized reinforcement is required. Key advantages include:

Pinpoint Fiber Placement: Precisely deposit fiber exactly where additional strength is needed without depending on purely geodesic paths.

Enhanced Tack & Steer: Because towpreg naturally possesses a tacky surface—further activated by mild heating—fibers can be accurately guided and laid on contoured surfaces.

Streamlined Setup: Combining AFP with FW in a single robotic system lowers the footprint, reduces capital expenditure, and cuts down on operational complexity.

Surface detail of tow-preg placement using TANIQ’s AFP Head and TaniqWind Pro Software.

A Single Robotic Platform with Automatic Tool Exchange

One of the biggest differentiators at TANIQ is our single-robot approach. Our system can automatically swap between a filament winding tool and an AFP head, both utilizing towpreg or similar pre-impregnated fibers. The result:

High-Speed Winding: Lay down continuous layers at rapid speed for the main structure.

Precise Local Reinforcement: Switch to AFP to add extra fibers in high-stress or complex geometry areas.

Optimal Efficiency: While hybrid heads exist, we achieve superior throughput and accuracy by changing between dedicated FW and AFP tools.

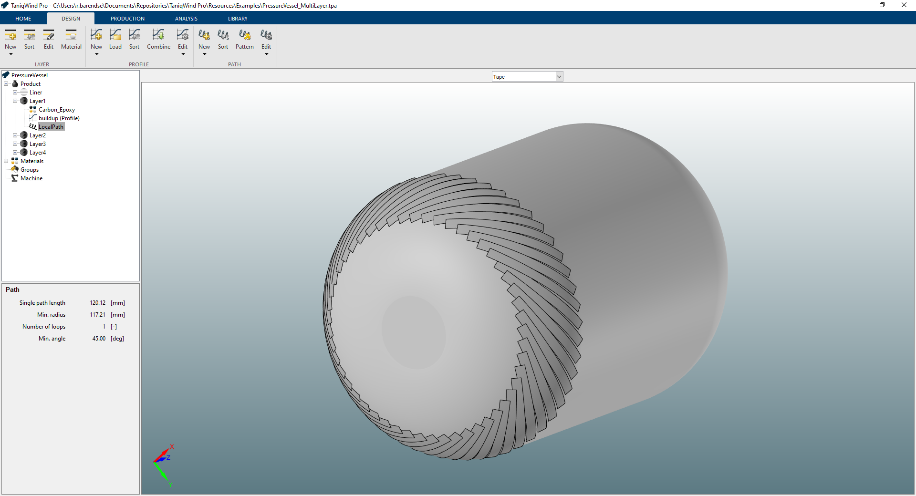

TaniqWind Pro: Unified Design & Manufacturing Software

Beyond hardware, software is critical to maximizing the potential of AFP and FW. That’s why we created TaniqWind Pro, a specialized CAD/CAM platform that integrates both processes:

Seamless Process Design: Develop continuous winding paths and localized AFP reinforcement within the same software environment.

Integrated FEA: Effortlessly export your hybrid designs into finite element (FE) models for Abaqus, making it easier to validate and optimize structural performance.

Automated Path Generation: Instantly convert your design into production-ready paths for robotic or CNC-based setups.

Screenshot of TaniqWind Pro software showing a doily pattern on a COPV mandrel.

Our vision on Uniting the Hybrid FW & AFP processes

Although we are on the forefront of developing this new Hybrid system, we acknowledge that this is only the start. To further develop this technology we will continue our R&D efforts on extending our TaniqWind Pro software and robotic winding systems to unify these two processes in a single, seamless and effortless system.

Leading-Edge Expertise

We’ve pioneered the concept of integrating FW and AFP, positioning ourselves at the forefront of composite manufacturing.Efficiency & Cost Savings

Our single robotic system handles both FW and AFP processes—cutting down on capital investment, factory floor space, and operational overhead.Next-Generation Software uniting FW and AFP

TaniqWind Pro unites FW and AFP design, simulation, and manufacturing in one intuitive interface.

Changing the Future of Composite Manufacturing

As industries ranging from aerospace to energy demand speed, precision, and cost-effectiveness, TANIQ’s integrated Filament Winding + AFP solution is here to redefine what’s possible. Whether you’re looking to build hydrogen tanks, pressure vessels, or any other critical composite structure, our approach—backed by robotic automation, widely compatible towpreg materials, and exclusive software—offers the flexibility and performance you need to stay ahead.

Ready to learn more? Get in touch with TANIQ to see how our hybrid system can revolutionize your composite manufacturing processes.