TaniqWind Pro - Functionality and Highlighted Features

Improve your composite design and production process with our powerful Features

TaniqWind Pro is developed by TANIQ’s winding experts based on their experience with the internal TaniqWind software used on a daily basis for challenging winding projects for over 14 years. This resulted in newly developed software, with a professional interface based on widely used CAD/CAM interface conventions. Using their experience with composite design and manufacturing they created an intuitive workflow guiding the user through logical steps working through the menu tabs from left to right. With a high demand for composite pressure vessel design from the market, a unique panel was developed, which makes it intuitive and efficient to design composite layers for pressure vessels. Furthermore, supporting the design and analysis of composite pressure vessels, a powerful FEA Toolbox has been developed, wherein the user can create an FE model, generate meshes, and export models to Abaqus and Hyperworks. The software also has advanced panels supporting the creation of production programs for CNC or robotic equipment. It has a unique panel for creating post-processors where the user can edit and customize to their requirements. Finally, it is the only software having a dedicated robotic post-processor, making it the go-to software for robotic winding.

Feature Overview

-

Continuous mandrel profile description

Coverage path algorithm

Adjustable start-winding-position

Constant in-plane curvature paths

Build-up model for tapes

Finite Element Model Export

Powerful post-processor

Production parameter integration

Robotic winding fully integrated

Local fiber placement

Software as a service (SaaS)

-

Mandrel data import feature (incl. DXF)

Pipes, Pressure Vessels and axis symmetrical mandrel geometries

Winding path & pattern generator

Geodesic and non-geodesic winding paths

Circumferential (hoop) winding

Helical winding

Transition layer winding

Segmented path option for designing advanced winding paths

Winding path and pattern simulation

Machine Program editor (e.g. Syntax, Declarations, etc.)

Customizable process settings panel (e.g. variable winding tension)

Highlighted features

Optimized Mandrel Definition

Instead of discretizing the mandrel surface into individual sections, TaniqWind uses a novel approach providing a continuous representation of the surface using an analytical model. This improved profile definition increases the accuracy of the winding paths, leading to improved product quality and smoother machine movements.

Improved profile description as continuous analytical surface

Increased accuracy of winding path calculations

Greater accurate and reliability FE results

Smoother machine movements

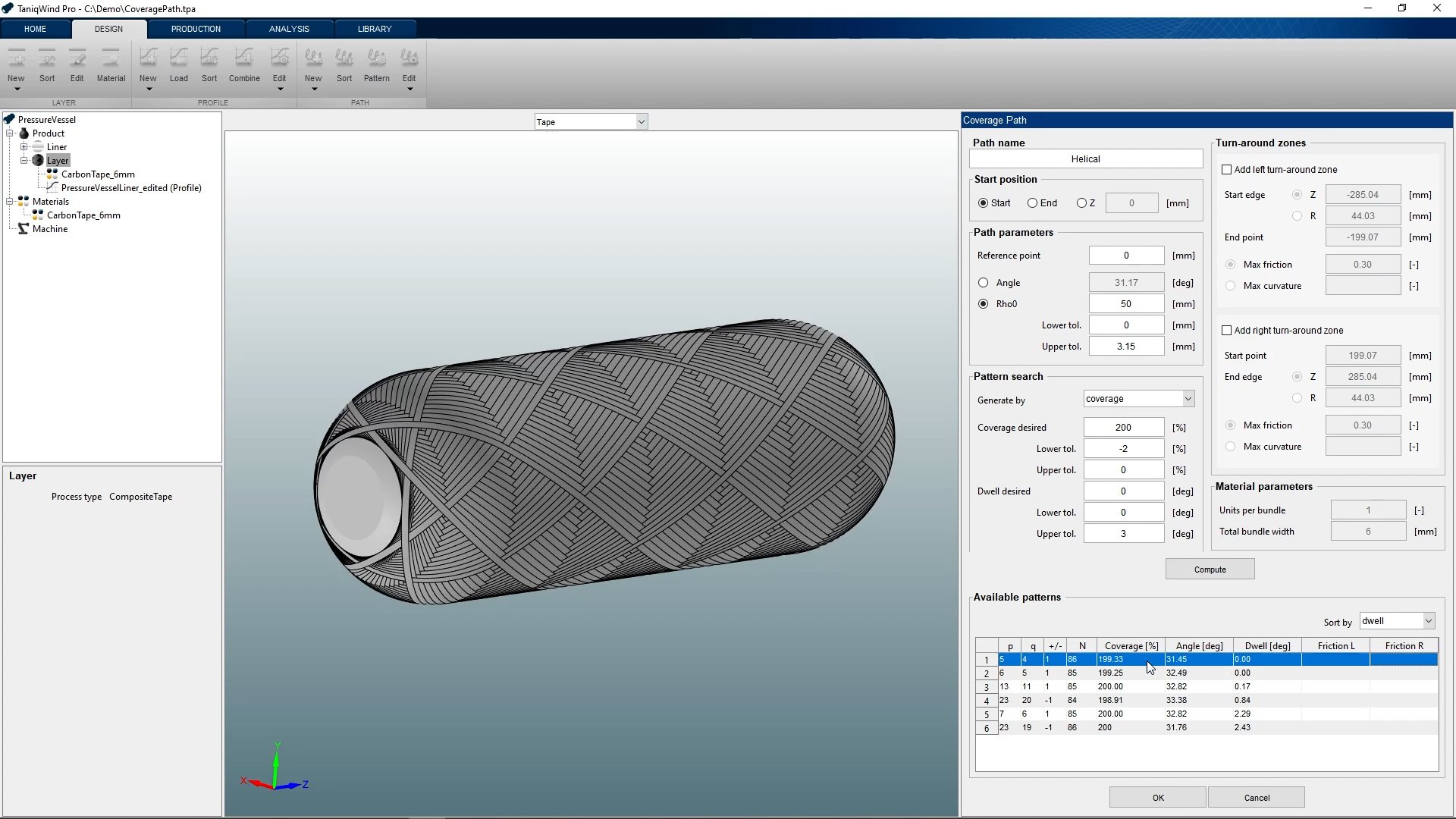

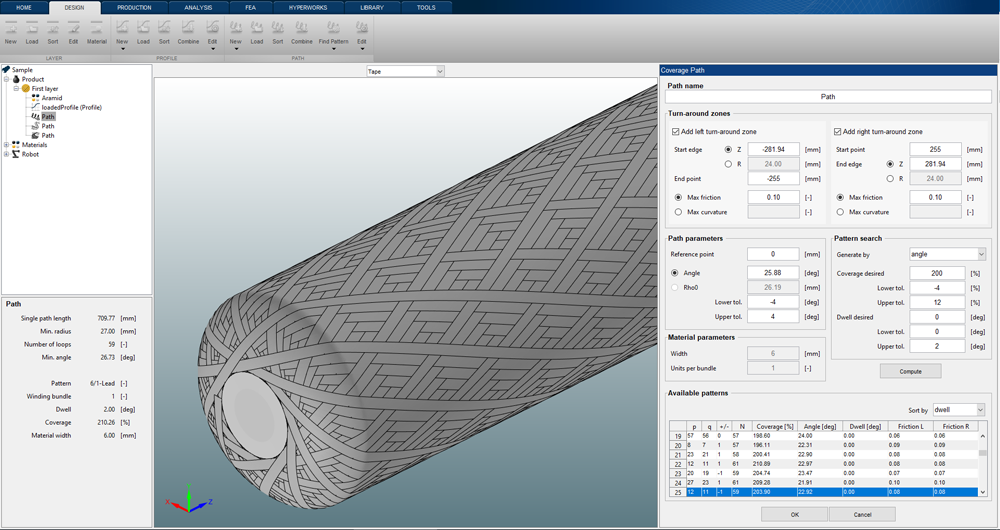

2. Layer Design Panel

TaniqWind Pro has a unique panel for designing composite layers. It has a coverage path algorithm that automatically searches for patterns corresponding to the requested coverage. This is achieved by automatically changing several parameters within a given bandwidth such as i) winding angle, ii) polar opening, iii) friction and iv) dwell. This functionality is especially useful for designing pressure vessels whereby a 200% coverage per layer is required, without gaps or overlap between adjacent tapes.

The software automatically searches for a composite layer within the specified bandwidth of the following criteria:

Coverage

Angle

Polar opening

Friction

Dwell

3. Adjustable start-winding position

TaniqWind has a unique function for shifting the start-winding-position to any location on the profile. Instead of having a fixed start-stop position, this position can be defined separately for each layer. This allows starting a helical layer at any desired position on the cylinder or dome sections. Spreading of the start-stop positions prevents local build-up and stress concentrations in the composite structure.

Start winding at any desired location along the profile

Start-stop positions are identical

4. Constant in-plane curvature paths

In addition to friction, constant in-plane curvature can also be used to generate non-geodesic paths. The constant in-plane curvature functionality creates tape paths using the maximum allowable in-plane curvature as the criterion. This feature is especially useful for tape placement processes where path trajectories are not defined by friction but are restricted by the maximum allowable in-plane curvature of the tape.

Design winding paths based on in-planar curvature of the tape to prevent buckling

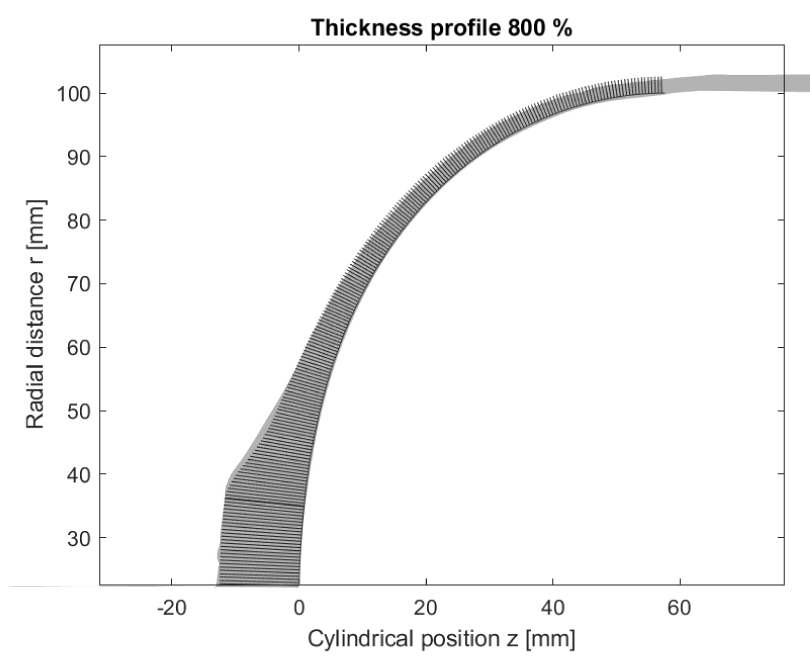

5. Build-up model for tapes

TANIQ has developed sophisticated mathematical models resulting in a powerful build-up prediction panel for filaments and tapes. In the panel, the calculated build-up profiles can easily be adjusted or smoothened. The improved build-up calculation provides accurate predictions of actual build-up behavior during manufacturing, drastically improving consistency between the Finite Element Model and the final product.

Advanced mathematical models to represent the build-up behavior

Optimized for critical product regions such as domes and polar openings for pressure vessels

Build-up panel with options for ‘smoothing’

Accurate match of actual build-up behavior during manufacturing

High consistency between the design, FEA model, and the final product

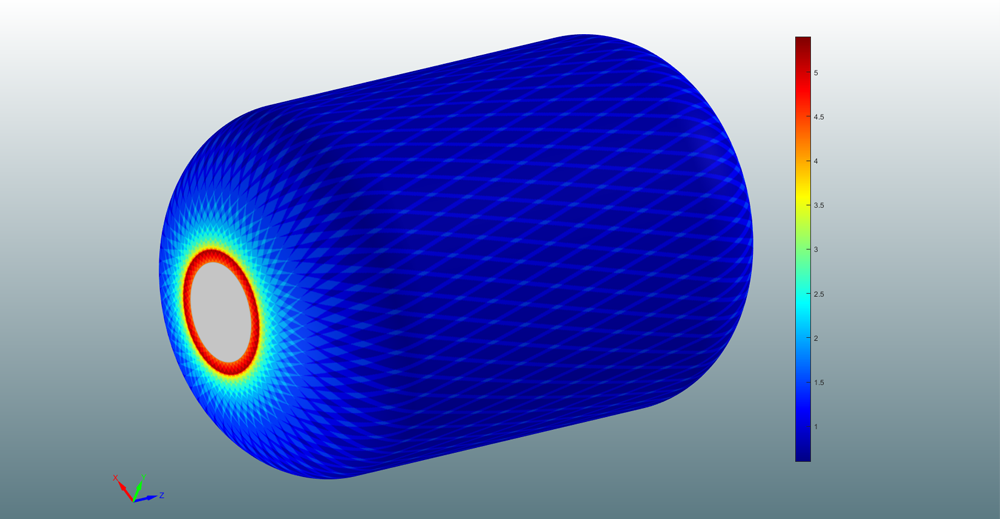

6. Finite Element Model Export

TaniqWind has an integrated FEA Toolbox functionality, with mesh generator, for exporting FE models to Abaqus and Hyperworks. It also supports a special shell element containing information on the number of tows and the individual tow directions per element, providing a high-fidelity data file, required for Altair’s Multi-Scale modeling approach.

Generate data files for FE models automatically

Generate and preview of meshing

Supporting Abaqus (shell, 2D axisymmetric and 3D elements)

Supporting Hyperworks (shell and 3D elements)

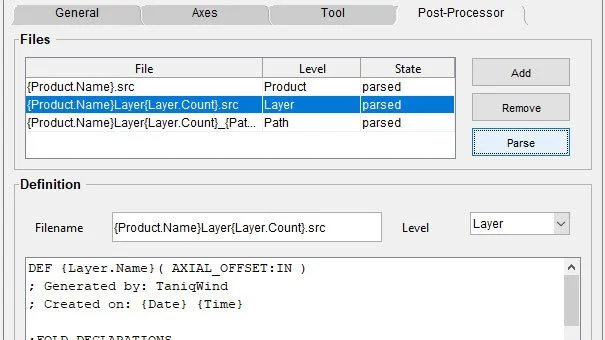

7. Powerful Post-processor

Within TaniqWind, users can define their Robotic or CNC winding machine and create a post-processor. In the post-processor panel, the user can customize the machine program and production procedure, having full access to the software computed trajectory (e.g. machine positions, orientations), providing users with a powerful tool for creating customized production programs.

Make post-processor for your robotic or CNC winding equipment

Maximum freedom for customizing your winding programs

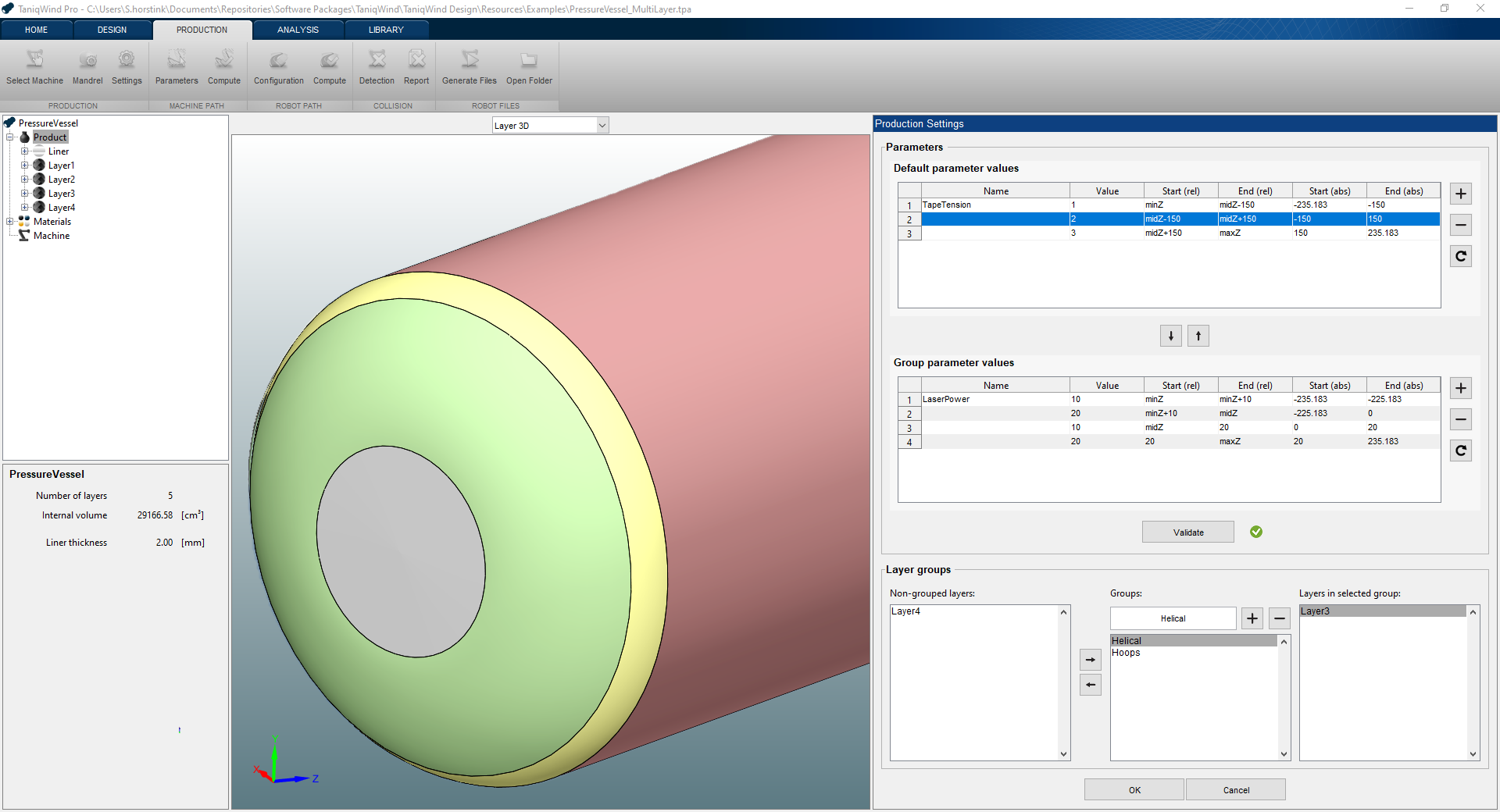

8. Production parameter integration

In the production settings panel, the user can define production parameters such as tape tension or laser power and set variable values for these production parameters per layer, and even per different section in the profile. Examples: varying the winding tension between hoop and helical layers or varying laser power for different sections within a layer.

Add and define process control parameters

Set variable values of process parameters for different profile sections

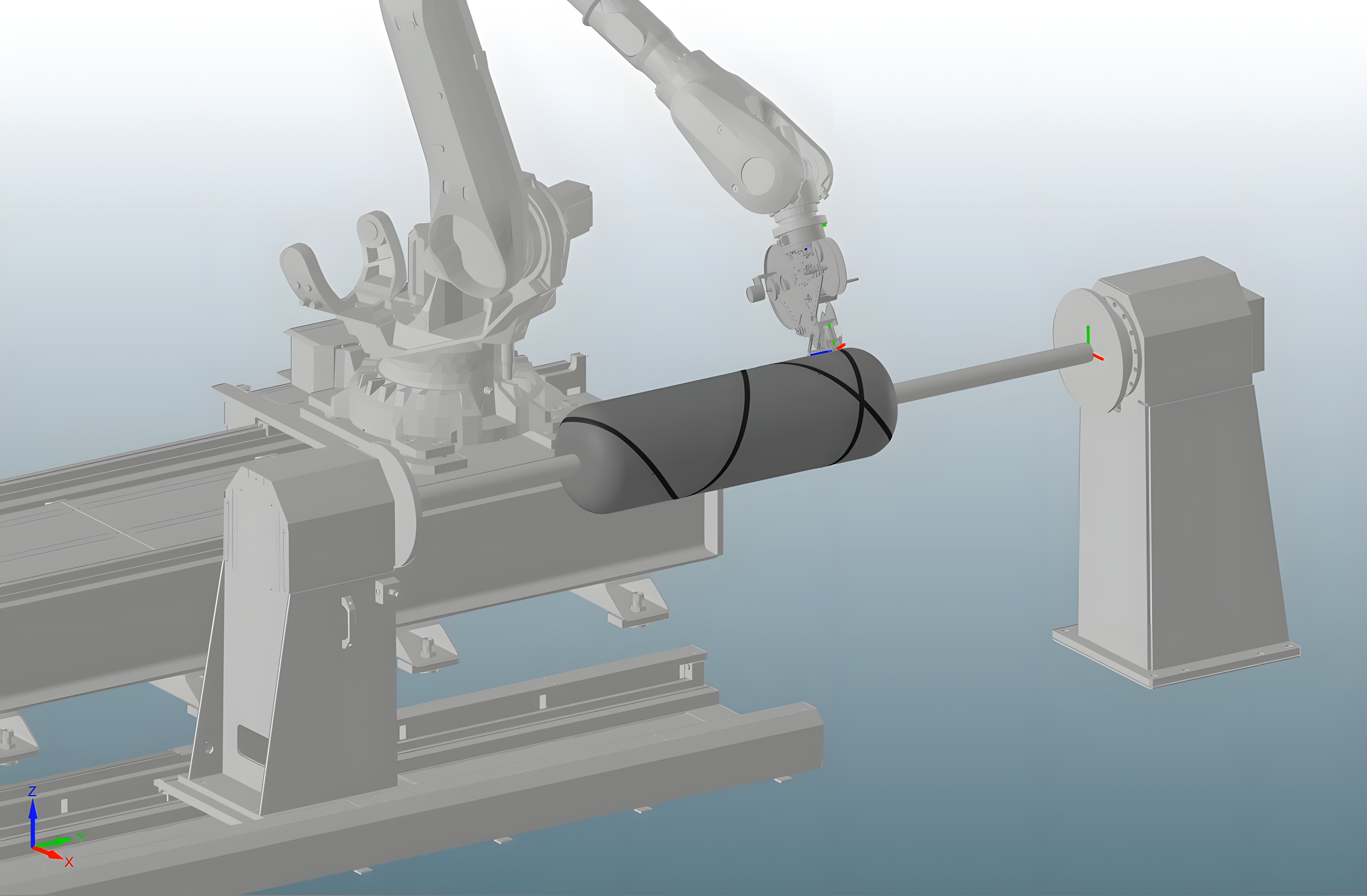

9. Robotic winding fully integrated

TaniqWind was developed in 2007 for Robotic Winding and has a dedicated robotic post-processor taking full advantage of all motion and control capabilities (instead of CNC movements being converted to robot movements). Some options within the software are defining a robot-held mandrel with stationary winding eye, defining an additional twist/yaw axis on the tool, and checking for reachability and singularity & collision detection.

Dedicated post-processor for robotic winding

Utilizing all motion capabilities of the robot

Including reachability checks and singularity & collision detection

10. Local fiber placement

With our recently developed Automated fiber placement, TaniqWind Pro brings a hybrid solution for optimized design and manufacturing of composites.

Optimize your composite design by using a hybrid process of filament winding and local reinforcement using Automated fiber placement. Within the Taniqwind Pro workflow, you can add local reinforcement paths and patterns, export FEA models and generate AFP placement programs between your filament winding sequence.

11. Software as a Service (SaaS)

TaniqWind can also be offered on a subscription basis, whereby the user can select the package (Lite, Extended or Full) and options that best fit their needs. The subscription model provides greater flexibility, scalability and cost-effectiveness. The TaniqWind subscription includes automatic updates and maintenance, providing users with access to the latest updates and improvements without additional costs or efforts.

Subscription-based model offering flexibility, scalability and cost-effectiveness

Including automatic updates & maintenance

Explore TaniqWind Pro more in-depth with our Tutorial series, designed to help current users maximize the capability of the software, and for those interested in gaining a deeper understanding of its powerful features.