Release Notes

November 2025

TaniqWind Pro v1.12

What’s New?

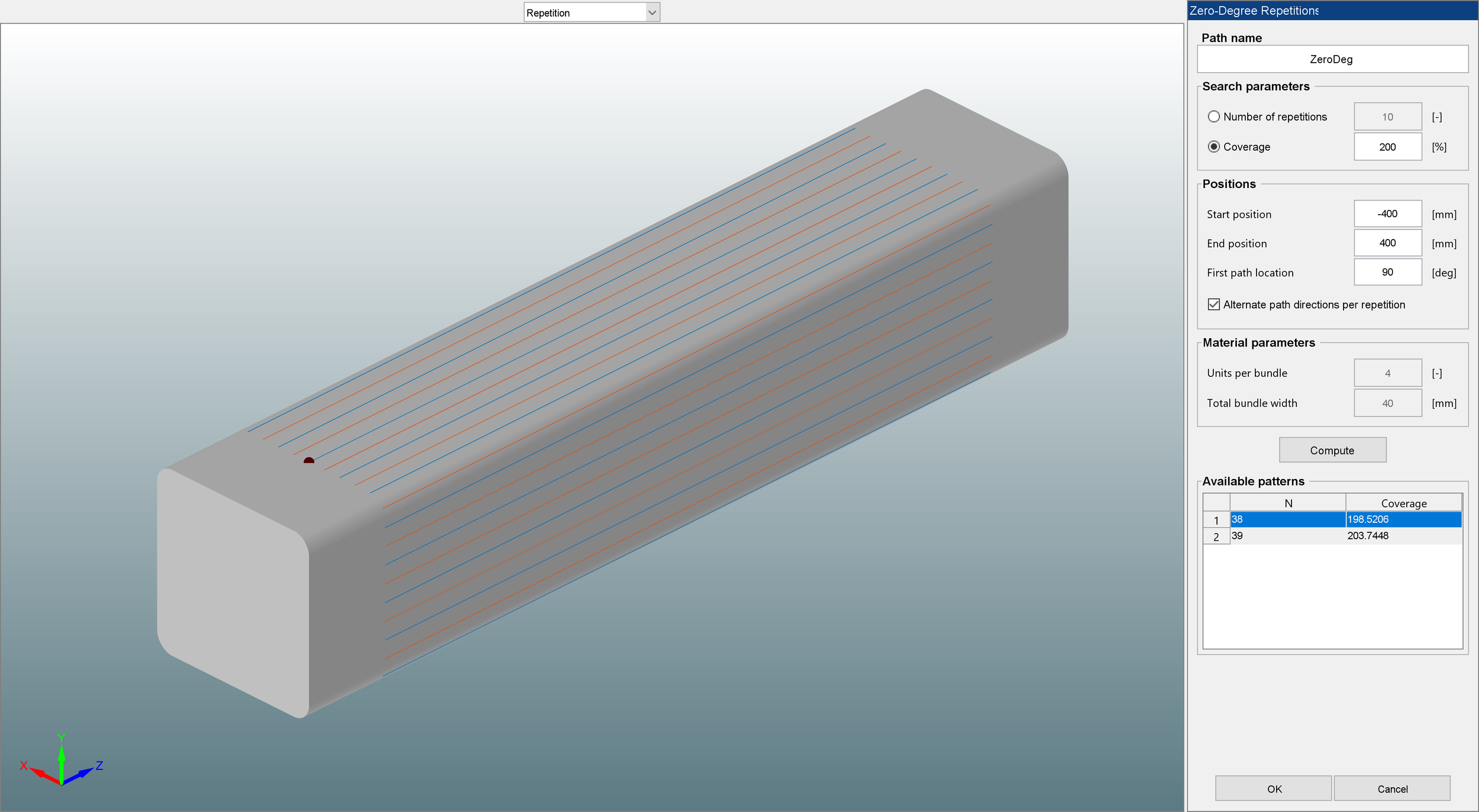

Support for alternating direction of zero-degree paths on rounded-rectangle mandrels

Zero Degree Panel with an option to alternate direction of zero-degree paths on rounded-rectangle mandrels

Other Improvements

Enhanced TCP (Tool Center Point) correction for CNC machines without a vertical axis.

Unified appearance of pattern tables.

Improved visualization after closing a panel.

Consistent term for payout axes.

Bug Fixes

Accurate identification of start and end points on steep profiles.

Fixed FEA 3D export error with XY symmetry.

Fixed trajectory computation error for CNC machines.

Corrected filtered fiber length at the top of bridging sections.

Correct geometry display in the machine library.

-

What’s New?

Editable build-up profiles across design sessions, giving significantly enhanced flexibility.

Transition path generation from the previous layer, ensuring continuity in winding paths, saving time and reducing errors.

Improvements:

Orientation-only movements now supported in smart filtering.

Enhanced visualization of filtered points.

Improved smart filtering eliminates closely-spaced points.

Trajectory settings persist after reset.

Panel lock during Helical Path with Pattern computation.

Bug Fixes:

Ensured correct identification of known materials in the loaded project file.

More accurate final point calculation in path generation.

Improved stability of mesh generation for axi-symmetric and 3D elements.

Smoother tool orientation at path start and end.

Faster filtering of long hoop paths.

Friction detection fixed on steep profiles.

Better error handling for initialized parameter values.

-

What’s New?

New Zero Degree Panel support for placement on non-axisymmetric rounded-rectangular tubes, enabling zero-degree path generation and placement trajectories on such mandrels.

Visualization of machine and mandrel movement in production simulation for rounded-rectangular geometries.

Extended post-processor syntax to support production file generation for user-defined machines.

Improvements:

Connectivity check now highlights radius and distance between paths.

Projects previous layer end point onto new profile.

Bug Fixes:

Base position computation for doily patterns

Incorrect material consumption for doily patterns in a loaded design

Corrupt file in one of the libraries (machine/material) no longer prevents startup of the software

Opening layup table prevented when doily patterns were present in the design

Added catching of error in trajectory configuration panel for non‐supported envelope type or winding radius

Profiles could not be uncombined

Fix for incorrect ply stacking in HyperWorks Shell Export

-

What’s New?

New Doily Pattern panel allows users to create a doily pattern type, enabling the repetition of a single path multiple times, equally spaced around the profile circumference.

New Netting-based analysis options allow quick analysis of pressure vessel performance.

Improvements

Improved FEA export for concave regions.

Direct sorting of paths when transition path is connected to an existing path.

Initialize layer names with an increasing number appended.

Allow definition of Transversely Orthotropic material model.

Required parameters updated for the Orthotropic material model.

Collision detection can now be aborted midway.

Bug Fixes

Fixed transition path generation bugs.

No more unexpected design reset when adding process materials to the library.

Fixed pre‐processing of HyperWorks shell model.

Fixed updating of reference point after turn‐around zone is enabled.

Fixed incorrect export of 𝜈31 material parameter to HyperWorks.

-

What’s New?

New layup estimator based on netting theory for pressure vessels has been introduced. Allowing users to estimate the required number of helical and hoop layers for a pressure vessel, given the target burst pressure.

New AllLoops repetition tag has been added to the Post‐Processor. Allows position data for each winding loop to be written separately

Improvements

Improved workflow to generate machine paths and trajectories

Faster software start‐up

Scrolling enabled in panels displayed on screens with low resolution

Renaming of nodes made easier

Product node shows 2D layer profiles by default when node is selected

Bug Fixes

Added indexing check to equation parsing in post‐processor

Corrected machine orientations for transition paths

Fixed bug causing profile buildup panel doing nothing

Other minor bug fixes

-

What’s New?

Machine movement in concave mandrel regions can be significantly smoothed using a new path bridging correction technique.

Improvements

Added buildup void factor warnings to the 2D-axisymmetry and 3D FEA export panels

Enhanced example machines

Enhanced transition path functionality

Reduced opening time for the Motion Profile panel

Corrected gr unit symbol to g and updated linear density descriptions

Bug Fixes

Resolved compatibility issue with older TaniqWind Design versions

Resolved Motion Profiling bug

Resolved dongle connections issues after sleep mode

Fixed error in machine path filtering for double points

Corrected blocking issue with envelope and constant tension machine paths

Improved handling of motion profile errors

Enforced positive friction values in the Transition Path panel

Prevented interruptions during table sorting

Other minor bug fixes.

-

What’s New?

Visualize bridging of a path over concave profile regions.

Support switch between Metrics and Customary unit systems for design and analysis.

Improvements

Streamlined product loading when unknown materials exist in the loaded product.

Path creation option reordered for faster design generation.

Parameter values of material models required FEA export are required before saving the material.

Warning displayed for irreversible actions.

Bug Fixes

Fixed a disappearing of payout geometry when changing payout definitions of a machine.

Editing of machine paths properly blocked when using smart filtering.

Fixed friction path calculation to avoid creation of long paths.

Fixed failed product loading if the associated machine contains unlicensed features.

Fixed irregular behavior of 2D plots when selected after 3D plots.

Fixed writing in wrong unit of relative yaw/twist coordinates for robotic tool axes.

Other minor bug fixes.

-

What's New?

Support free grouping of layers for bulk operation of assigning materials, and computing machine paths and trajectories.

Support setting product‐dependent winding speed in post‐processor definition files.

Improvements

More informative interface for generating a coverage path.

Enable users to define certain robot geometry parameters as negative or zero.

Uncombine option removed from context menu when no longer applicable.

Remove irrelevant settings in the panel for creating a new general layer.

Bug Fixes

Updating the license from within the software no longer shuts down the software.

Visualization and computation in Hoop Path panel made more robust.

Creating a buildup profile from a profile reaching zero radius is now more robust.

Fixed production computation issues when using a CNC machine with reduced degrees of freedom.

Fixed error that blocks the creation of an offset profile.

Editing the filtering condition of a single machine path now works correctly.

Improve input parsing robustness in panels.

Ensure correct visualization of payout axis rotation direction.

Other minor bug fixes.

-

What's new?

Updated hoop path panel to support creating multiple hoop passes at once.

Added context menu option to path node to delete all path nodes in the layer at once.

Enabled machine path parameters setting and computing for all layers at once.

Added support for robot to motion profiling.

Added velocity and acceleration as parameters of the robot TCP position, orientation, mandrel axis and track.

Improvements

Improved orientation cut‐off when using combination of yaw and twist to minimize shear and/or twist in the material.

Limited support of certain yaw settings for robotic machines to ensure computational integrity for orientation.

Stop supporting using only the yaw axis on the tool.

Stop supporting trajectory orientation settings using twist orientation with extra yaw axis.

Upgraded to MATLAB Runtime version R2024a.

Added footnote to error dialog box for sharing files.

Bug Fixes

Fixed axis resolution sign in robot extra axis panel in the machine library.

Fixed displayed tape width for multiple tapes per bundle in simulation and suspended tape plot.

Other minor bug fixes.

-

What's New?

Plot options that shows shear, twist, twist per meter and tape for trajectories.

Support for floating software licenses.

Improvements

Polynomial approximation to path coverage plot.

Support for triangular elements for shell export.

Proper error handling to motion profile panel in case orientation out of bounds.

Removed Export button from toolbar Home tab.

Project saving process abortable with no TPA created.

Improved check between existing paths and edited materials when closing material libraries.

Better functionality to contact Taniq and sending error reports.

Updated motion profile panel to delay computation of a layer when opening the panel.

Updated motion profile panel to disable controls for non‐existing axes.

Updated check for profile validity when loading from file.

Updated robot reachability check to include track within limits check.

Bug Fixes

Updated preferences panel to check whether user has write access to set folders.

Fixed ellipses from .dxf file to be loaded incorrectly in some cases.

Fixed profile corner rounding to fail for some cases.

Fixed trajectory filtering showing a duplicate point error in some cases.

Fixed object reference counter not to be reset when looping through objects with repetition tag.

Other minor bug fixes.

-

What's New?

Option to initialize the material of a new layer material from the previous layer.

Display winding position, velocity and acceleration of individual CNC axes of the current design.

Support user geometry for the payout element of the tool for both CNC and Robots.

Improvements

Consistency and clarity of FEA export panel plots.

Contact Taniq button added for directly emailing Taniq for support.

CNC post‐processor example based on a Siemens controller added to CNC_4AxisEye_cnc2To4Axis.tmsd.

Bug Fixes

Minor bug fixes.

-

What's New?

Start winding position is now indicated in 3D plot of the selected path.

Mandrel is visualized at location defined by axial offset in the machine 3D plot.

Support winding with multiple units per bundle.

Buildup profile computation supports user defined polynomial smoothening in the turn‐around zones.

Improvements

HyperWorks

Nominal winding angle of a ply now uses the angle at the reference position of the corresponding path.

Correct unit conversion implemented.

Improved uniformity of the mesh seed.

Added a warning when mesh size is larger than the tape width.

Abaqus

Improved uniformity of the mesh seed.

Added a warning when mesh size is larger than the tape width.

HyperWorks 3D solid export

Supports exporting the design using 3D solid elements for Hyperworks.

Abaqus 2D‐axisymmetric and 3D solids export

Supports exporting the design using 2DA and 3D solid elements for Abaqus

Bug Fixes

HyperWorks

Fixed incorrect drape angle and thickness assignment when the winding angle of the ply does not start at 90 deg.

Abaqus

Fixed incorrect drape angle and thickness assignment when the winding angle of the ply does not start at 90 deg when using tow‐tracking.

Fixed incorrect drape angle assignment by correctly considering the tape width when using axisymmetric option.

HyperWorks 3D solid export

Fixed a known issue where the meshing process is unstable in concave product sections (e.g. connection between the vessel and the boss).

Abaqus 2D‐axisymmetric and 3D solids export

Fixed a known issue wh the meshing process is unstable in concave product sections (e.g. connection between the vessel and the boss).

Other minor bug fixes.

Previous Release Notes