Composite Technology

TANIQ develops technology for the design and manufacturing of composite parts

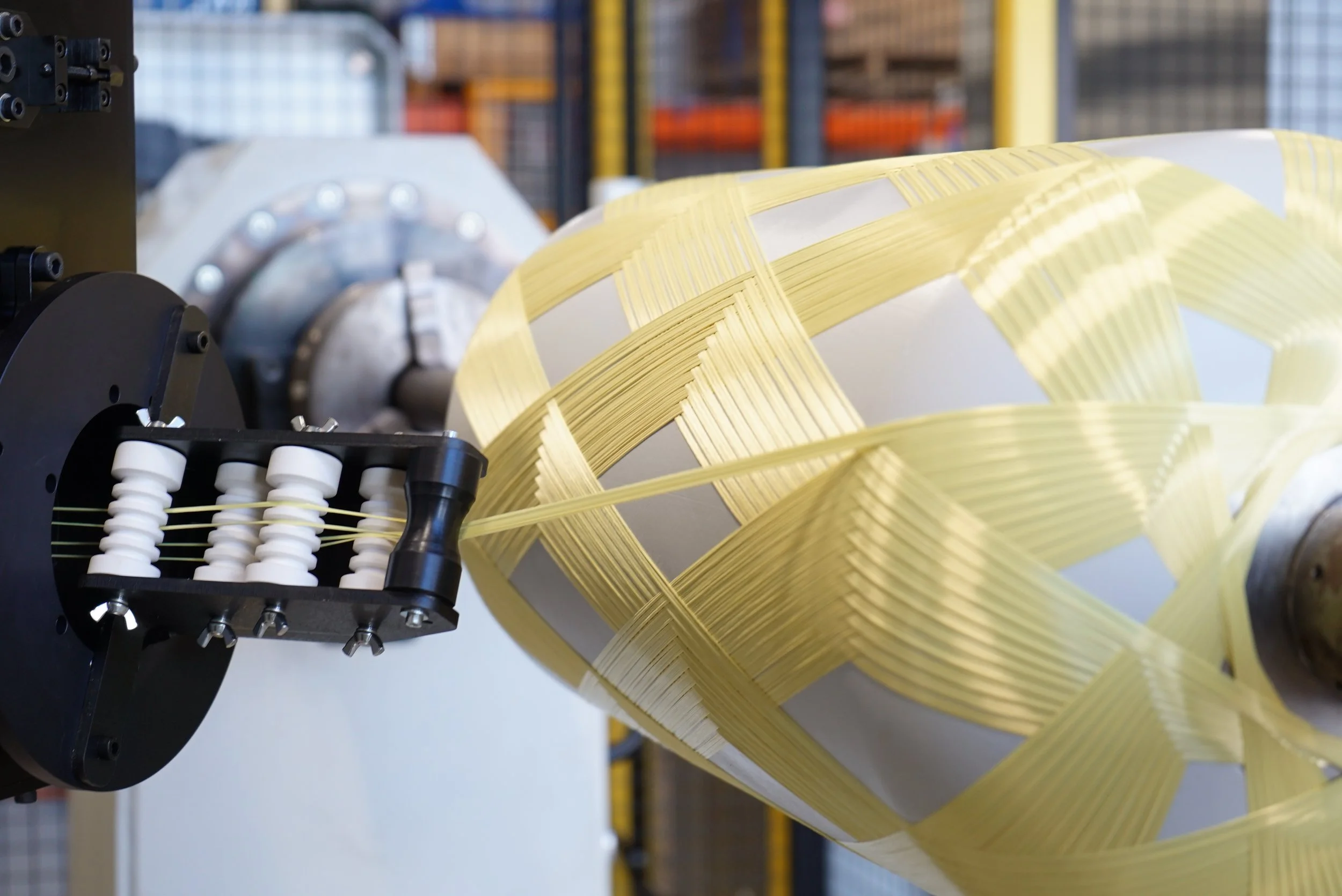

Starting as a spin-off from the Aerospace Faculty of Delft University of Technology, in 2007, TANIQ developed one of the first robotic winding systems in the world. Since then TANIQ has done extensive R&D in composite design and robotic winding technology. This has resulted in a Composite Technology Platform built around expertise in robotic winding, and vast knowledge of composite product development and automated production. TANIQ works in close collaboration with Universities and Research Institutes, and supports our clients with developing innovative solutions and implementing these in their R&D or production set-ups.

TANIQ has nearly 2 decades of experience with robotic filament winding during which they have developed winding systems for complex shaped parts in demanding industries worldwide. During these projects, complex winding challenges were solved by a combination of software and hardware-related solutions. Today, TANIQ is the most experienced robotic filament winding company in the world, leading the development of new technology in this field.

Filament winding technology has been used since the 70s for manufacturing lightweight composite parts for the aviation and aerospace industry. In 2007, TANIQ was one of the first companies worldwide to use an industrial robot for filament winding, which introduced new capabilities in terms of degrees-of-freedom for the winding process, combining various processes into one system (e.g. FW and AFP), and integrated automation tasks executed by the robot.

Filament Winding Technology

Thermoplastic AFP is the process of applying thermoplastic tape on a mandrel while adding pressure and heat for in situ consolidation, or out of autoclave (OOA) processing. Using dedicated Tape placement tools it is possible to place single or multiple tows on complex shapes.

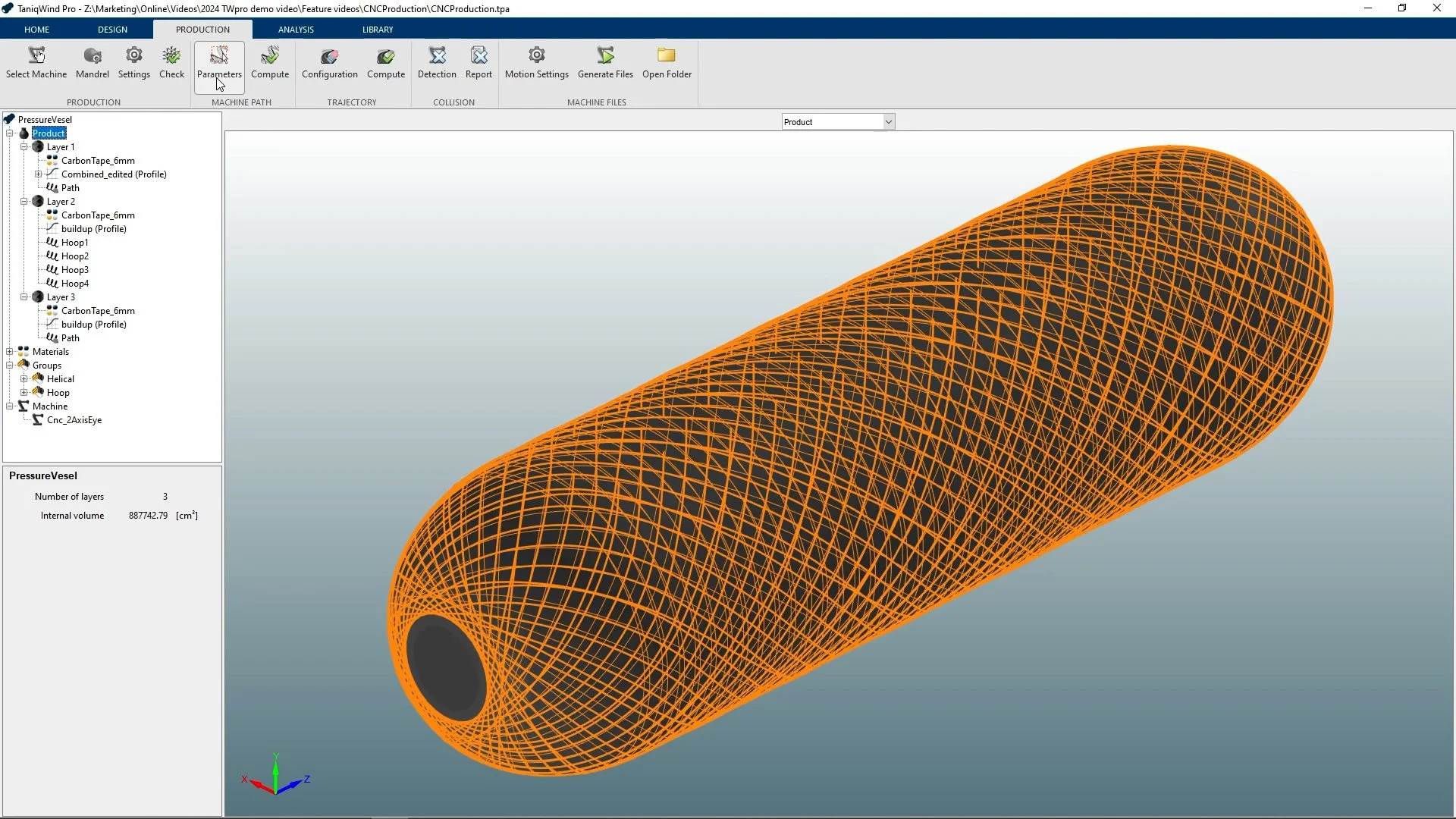

TANIQ has experience with the development of thermoplastic composite pressure vessels, combining continuous tape winding whreby the pressure roller follows the mandrel surface to apply pressure, combined with local placement of local reinforcement on the dome areas. In TaniqWind Pro, the user can define variable values for process parameters such as laser power, or compression force, proportional to the speed profiles at different product sections. Furthermore, continuous winding paths and local paths can be created within a single software and exported as a single production program for the robot.

Winding with thermoplastic tape also results in other process characteristics such as different built-up behavior (especially in the dome areas and polar openings) and buckling of the tape when using small radii winding paths. TaniqWind Pro has built-in solutions dedicated to tape winding, such as the in-planar curvature criteria for tape paths (instead of a friction criterion).

Thermoplastic Automated Fiber Placement

Towpreg material introduces powerful capabilities for both filament winding and automated fiber placement. Combining both processes allows to benefit from the high winding speeds achievable by filament winding, combined with the ability to add local reinforcements by AFP.

TANIQ has developed a unique hybrid system combining the filament winding and automated fiber placement into a single design software (TaniqWind Pro) and a single robotic winding system, comprising a FW Tool and AFP Tool. The integrated solution offers a smooth design workflow and seamless integration of both processes into a single production system.

TANIQ has applied hybrid towpreg FW and AFP processes for composite pressure vessels and specialty applications for aviation and defense industries.

Towpreg FW & AFP

Dry winding is a filament winding process without the use of resin for impregnation of the fibers, resulting in dry-wound fibers. The absence of resin has advantages in terms of winding speed, material costs and a clean process.

After the dry winding, the semi-finished product can be impregnated with an epoxy-based resin system in vacuum conditions. Alternatively, the dry wound product and can be covered with a protective (spray-on) coating.

TANIQ has experience with dry winding of complex bellow shapes, large diameter rotors and composite pressure vessels. TAfter the dry winding, the semi-finished product is impregnated with an epoxy based resin system in vacuum conditions. This makes the resin completely dip the fibres (or the fabric), eliminating by definition any presence of air inside the product. TANIQ is performing ongoing R&D on dry winding of thick-walled parts, investigating and optimizing the technology.

Dry Winding