Interview with Blackwave

Customer Interviews

In this customer interview series, we talk with our Clients about how they experience working with TANIQ.

Interview with Janis Mörk, Product Owner from Blackwave GmbH

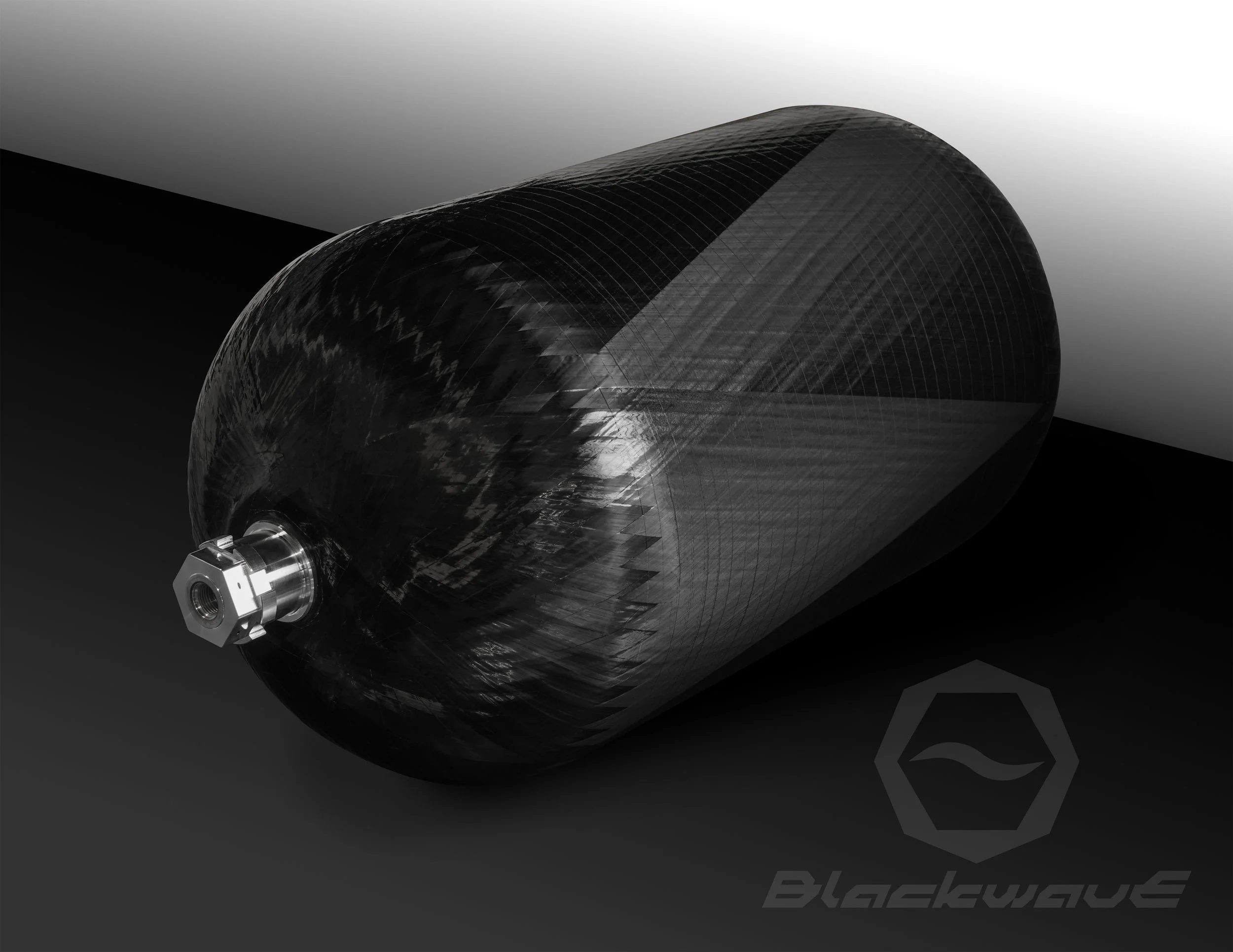

Blackwave GmbH (Munich, Germany) specializes in the development and production of high-performance carbon fiber reinforced plastic (CFRP) components, particularly pressure vessels for the space industry. Blackwave contacted TANIQ, because they wanted to replace their filament winding software, to improve their design workflow and robotic winding capabilities.

"The people working at TANIQ have a lot of experience with robotic filament winding and know the challenges regarding winding and winding software. Feeling like having the same understanding of the problems and challenges we are facing and potential solutions made us confident in working with TANIQ.”

Blackwave engineering working with Taniqwind Pro (Image courtesy by Blackwave)

Can you introduce Blackwave, the type of composite products you specialize in and their industries/applications?

Blackwave specializes in the development and manufacturing of composite overwrapped pressure vessels (COPVs) for space applications. Our products serve as fuel tanks in satellites and secondary high-pressure tanks in launch vehicles – especially engineered for the unique loads and strict qualification standards of the space industry.

We engineer high-performance products that demand precision at every level - including the software behind it. That’s why we use automated, repeatable processes like filament winding, backed by extensive simulation and rigorous COPV testing.

What challenges did you face in filament winding design/manufacturing before using TaniqWind Pro?

One of the biggest challenges before we started using TaniqWind Pro was the programming of our winding machines. We have tried other software solutions before, but they did not work for us. Mainly the inaccuracy of the fiber placement made the process iterative with trial and error in order to place the fiber at the desired location. It was hard and time-consuming to match the designed fiber layers exactly on the part. With TaniqWind Pro the layers get placed at the right positions with only minor adjustments necessary.

What made TaniqWind Pro the solution you felt confident moving forward with?

On the technical side, the biggest advantage of TaniqWind Pro for us is the possibility of using the same digital model for both simulating a COPV and manufacturing it. Thus, moving from a digital design into hardware is very fast and the manufactured product matches the simulated design very closely. The accuracy between simulation results and actual hardware tests is very good with this workflow. This is necessary for the application of our COPVs as they are used in a highly critical application with small safety factors. We have been able to validate the predictions coming from the FE simulation with a lot of tests over the last years.

Additionally, the people working at TANIQ have a lot of experience with robotic filament winding and know the challenges regarding winding and winding software. Feeling like having the same understanding of the problems and challenges we are facing and potential solutions made us confident in working with TANIQ.

Which feature(s) or aspect(s) of TaniqWind Pro have had the most noticeable impact on your workflow?

The close matching between the manufactured hardware and the simulation of the COPVs really helps to accelerate our COPV development. Trying out multiple layups digitally in simulation in a very short timeframe enables us to optimize the layup even before starting to manufacture and test hardware. A lot of design iterations can be done digitally already to improve the design. And when manufacturing the first prototype of a product, we can rely on the layup being close to what we expected.

All this enables us to develop a new product within months and use an iterative design and prototyping approach to our advantage.

How was the process of integrating TaniqWind Pro into your existing setup?

Integration of TaniqWind into our design and simulation workflow went smoothly, as it already comes with FE-mesh export for our FEM-software. In addition, the learning curve using TaniqWind Pro is fast with a well-written user manual and helpful video tutorials.

Changing the programming of our winding machines to TaniqWind Pro was also quite fast. With some support by TANIQ team, we were able to write the post-processor for our machine configuration. After that, we were ready to use it for pressure vessel manufacturing right away. Also, setting the software up for a new winding machine is not complicated.

How would you rate the quality and availability of support by TANIQ?

When we had issues working with TaniqWind Pro, we got fast response and qualified help from their support team. Getting support directly from the technical team at TANIQ helped to solve our problems, as they know their software very well and are also experts in robotic filament winding. We received valuable online support on topics like post-processor settings or winding speed increase, but also on simple bug fixes.

Are there new developments you’re planning to explore using TaniqWind Pro?

We are checking out the new software features like local reinforcement layers and evaluating if our products can benefit from it.

How do you see your partnership with TANIQ evolving in the future?

One of the greatest benefits of the partnership with TANIQ is the open exchange about the software, including current limitations, problems we run into and planned software features. We feel like our input as a customer is valued and the software is also improved based on our feedback.

We are keen on continuing this open exchange and both increasing our knowledge and capabilities.

What would you say to companies considering TaniqWind Pro?

In general, TaniqWind Pro should be considered by companies working with filament winding or design/simulation of wound products. Especially if you want to close the loop between design and manufacturing, TaniqWind Pro is a great solution.