JEC Paris 2026: TANIQ to Showcase Multi-process solution combining FW, AFP & Rubber winding

TANIQ will exhibit at JEC World 2026 in Paris to present their latest developments: a multi-process and multi-material manufacturing solution that combines filament winding (FW), automated fiber placement (AFP), and rubber winding in a single integrated software and robotic solution.

Advanced Composite products are increasingly moving toward multi-material and multi-process concepts. A well-known application is a composite pressure vessel, that can be optimized to increase production speed and save material, by combining high-speed filament winding, with precise local reinforcement in the dome areas using AFP.

The challenge is that manufacturers are dependent on combining different software packages and different machines. Using separate software and machines, requires data exports, and product changeovers between machines, resulting in an error-sensitive process, and long lead times. Therefore, TANIQ is integrating these multiple processes into a single workflow — one software environment and one automated robotic system.

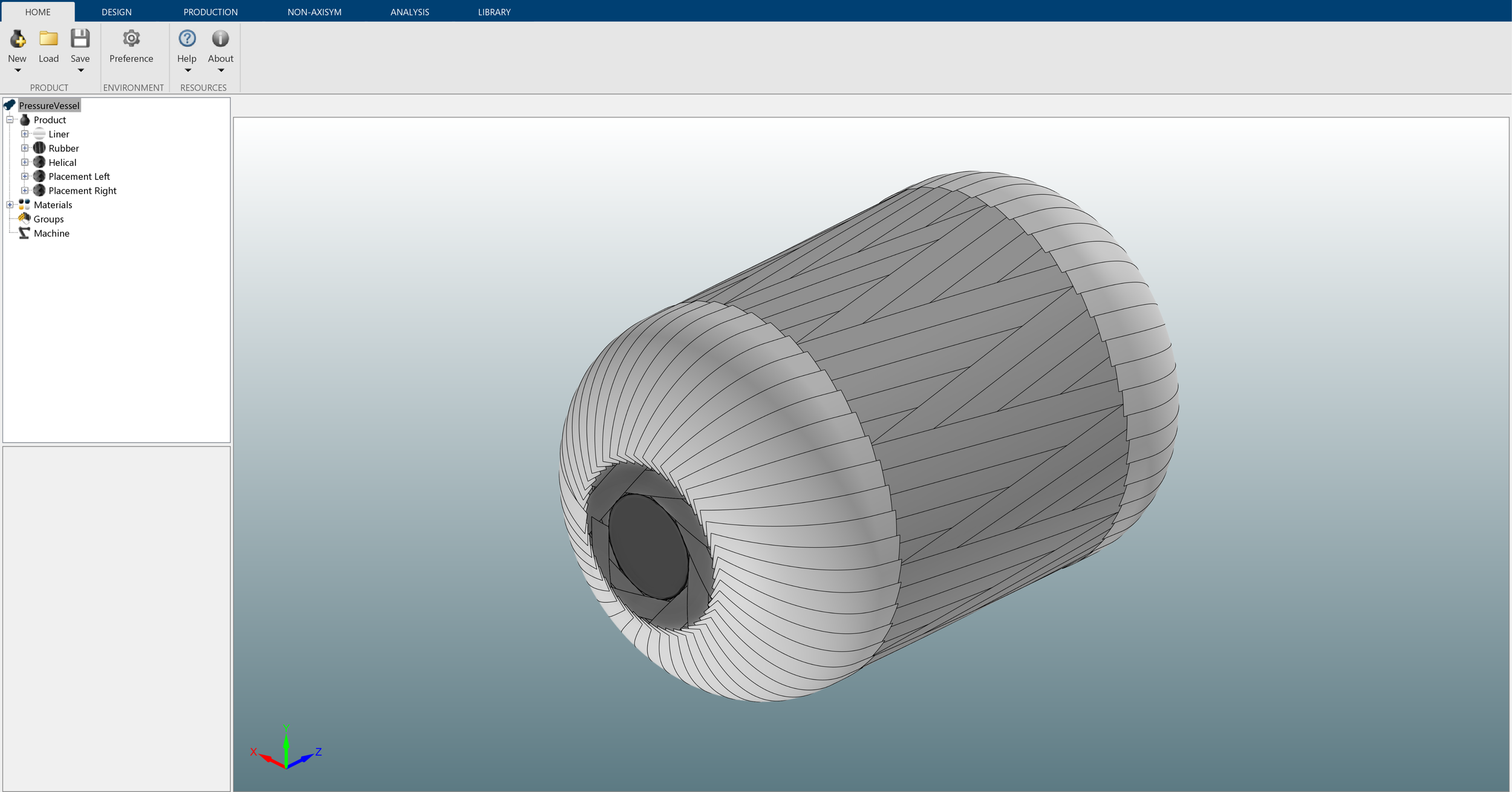

Rubber layers, filament winding layers, and AFP layers all integrated in a single design in TaniqWind Pro

One software environment: from design to production

At the core of the solution is TaniqWind Pro, TANIQ’s proprietary design and manufacturing software, developed to support a unified workflow for:

Filament Winding (FW)

Automated Fiber Placement (AFP)Rubber Winding (RW)

With all processes integrated into one software environment, users can engineer and program multi-process structures within TaniqWind Pro, effortlessly combining FW, AFP and RW layers into a single product design. The unified design can be exported to Abaqus FEA software for analysis and optimization. This unified software solution reduces the need for file transfers and manual layer rework, reducing the risk for errors, and improving the design quality and reliability.

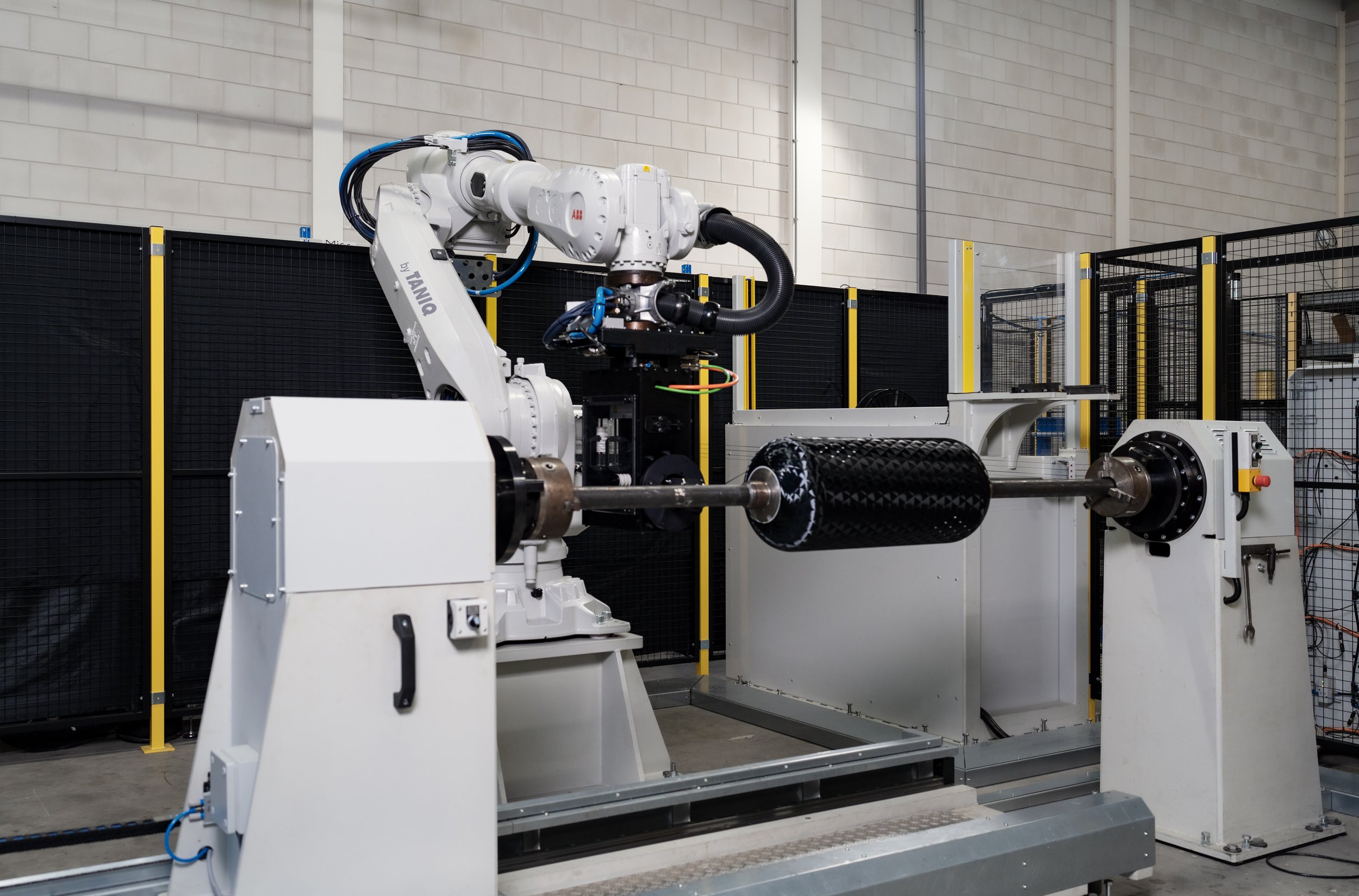

Robotic winding system developed by TANIQ

One robotic cell: automatic tool switching between processes

To execute the integrated manufacturing strategy, TANIQ’s robotic winding system supports multiple interchangeable tools on the same machine. Depending on the process step required, the system can automatically switch between:

a dedicated high-speed Filament Winding Head

an AFP Head for local reinforcement

a Rubber Winding Head for integrated elastomer reinforcement steps

This enables continuous manufacturing without part exchange between machines, improving product quality and repeatability, and significantly reducing lead times.

Unique capabilities for Rubber Winding

TANIQ is renowned for its unique Rubber Winding technology, applied to high-end rubber composite applications since 2006. The Rubber Winding solution comprises a combination of path generation algorithms and advanced control strategies for the winding of low-modulus rubber materials. TaniqWind Pro is the only software that has a Rubber Winding path functionality, and is coupled to TANIQ’s proprietary Rubber Winding Head, which together enable the winding of accurate rubber layers for sealing, insulation, or protection.

Enabling new product architectures

By bringing multiple processes together into one system, TANIQ’s technology enables manufacturers to produce structures that previously required separate process steps, machines, or manual operations. Applications include composite overwrapped pressure vessels (COPVs), hydrogen storage systems, rocket motor cases and other lightweight structures, as well as reinforced rubber and composite-rubber products requiring multi-material reinforcement concepts.